Process Datasheet

Process Datasheet

For efficient operations and high productivity in the world of business processes, accurate and efficient information management is essential. Process Datasheet is one such vital tool for all oil and gas jobs. From architecture and production to oil and gas, process datasheets play a vital role in ensuring smooth communication, facilitating equipment procurement, and driving productive decision - making. The importance of operation datasheets, their construction, and how they streamline operations in various industries will all be covered in this article.

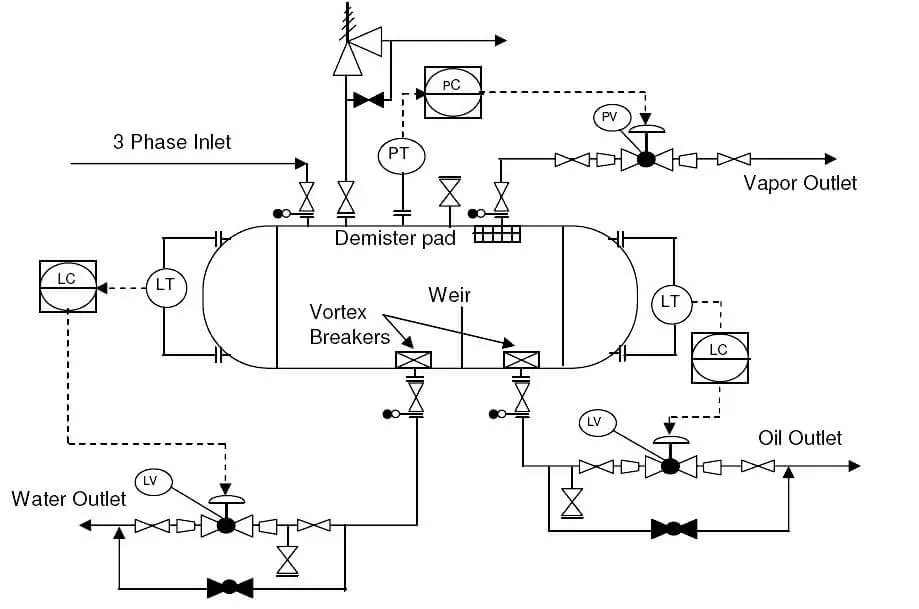

Method datasheets are one of the crucial process deliverables produced during a project's in-depth design phase. Every project must define every piece of equipment, and process datasheets must estimate the equipment prior to purchase. Once the Process team prepares the P & ID( Piping and Instrumentation Diagram ), the next phase is to create process data sheets for each piece of equipment. To get prices, these process datasheets can be sent to vendors or vendors.

A Procedure Data Sheet: What Is It?

A procedure datasheet summarizes how well a system or piece of equipment performs. The procedure sheet for starting the detailed design specifies the technical characteristics of the equipment or system. They are also referred to as operation equipment or design datasheets. All the fundamental technical requirements( Design Data ) to specify equipment( technical specification ) are provided in the process datasheet.

A unified source of information about a particular part or piece of machinery used in an industrial process is provided by procedure datasheets. These papers provide a standardized format for capturing essential technical information, specifications, and operational requirements. Procedure datasheets act as a bridge between executive and purchasing teams, enabling effective collaboration and reducing the risk of confusion.

- Understanding Procedure Datasheets

Construction and Components of Method Datasheets

Procedure datasheets for oil and gas industries usually contain the following sections:

General Information:

The name of the products, its tag number, and a brief explanation of its purpose are all included in this section. It provides an overview of the car's goal and its inclusion within the general procedure.

Process Parameters:

Here, essential process parameters are documented, including temperature, pressure, circulation rates, and any other related operational variables. These criteria aid in figuring out whether the machinery is appropriate for a particular method.

Design and Construction:

This section outlines the car's design specifications, building materials, dimensions, and assembly requirements. It ensures that the purchasing group you select the right equipment that aligns with the operation needs and meets industry standards.

Performance and Efficiency:

Process datasheets emphasize the performance characteristics and performance metrics of the gear. This data assists in evaluating the car's ability to meet output targets, energy performance goals, and overall process optimization.

Overall each method datasheet often includes:

General size of the equipment

Variety of equipment,

approximate geometry( length, diameter, etc. )

Recognition of the tie-in point connections and nozzle,

Materials used in the construction of the equipment( material, corrosion allowance, cladding, and lining requirements, etc. )

Full range of operating conditions( Design Pressure, Design and Operating temperature, Test Pressure, Fluid Type, etc ).

Certain information and remarks.

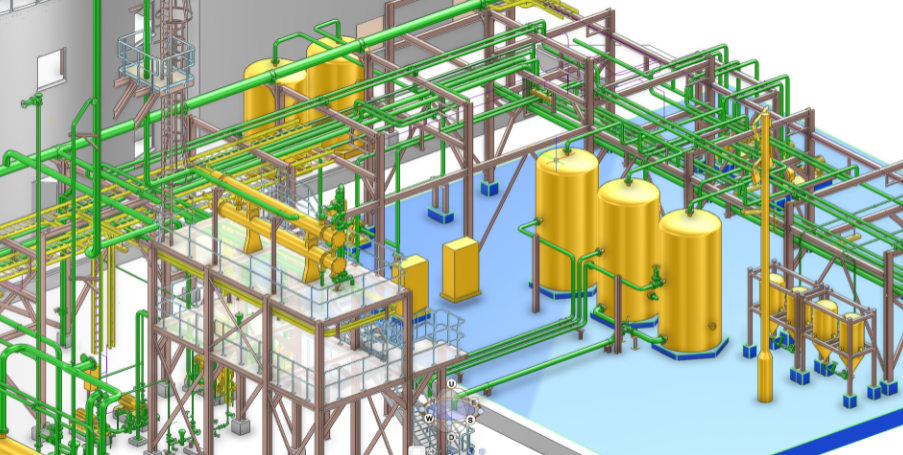

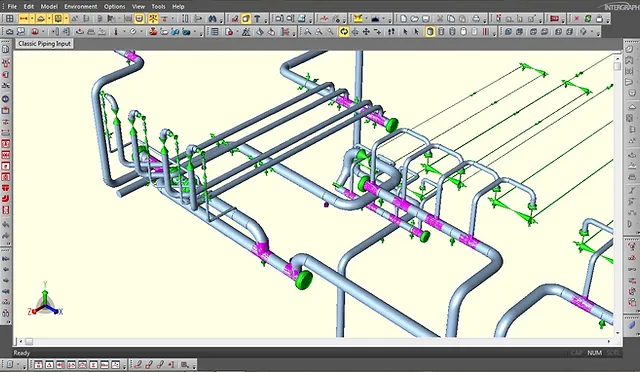

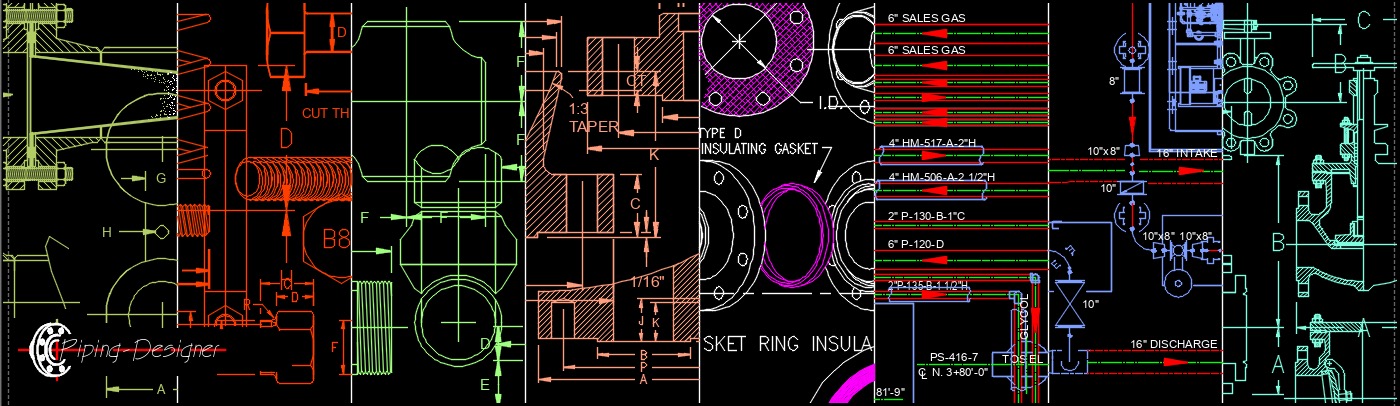

The Process Datasheet often includes a basic diagram to quickly communicate the technical specifications to the merchant, supplier, or clients. Technical datasheets for a piece of technology are often prepared using the method datasheets as a reference. Fig. 1 beneath shows an example of a typical process sheet pattern.

Created by

Comments (0)

Popular categories

Piping Design Engineering : Basics

4Piping Design Engineering : Basics

2Latest blogs

Pipe Modeling using AVEVA E3D software

Tue, 17 Oct 2023

The Basics Of Piping Stress Analysis

Tue, 17 Oct 2023

Piping & Instrumentation Diagrams : P&IDS

Tue, 17 Oct 2023

Write a public review